Following on from last year's re-spraying of the offside wing and door panels, the time has come to give the nearside wing some TLC.

Historically, it also has suffered from lacquer peel which seems to have been the major downfall of Hx over the years.

Sometime last year, I removed all the remaining lacquer using a hand held Stanley blade and a stubby nylon brush. The upper 'shoulder' of the wing has also suffered a dent through actions not of my own.

Clearly this dent will have to be removed before any painting is undertaken.

Took the above photo using sidelight to show the dent on the shoulder of the wing. The matted surface of the wing minus its lacquer coat stands out when compared to the door panels. Also visible is another small dent on the front door panel, a scratch on the bumper forward of the wheel and the faded state of the black wheel arch brow.

Even at this stage, I thought about simply replacing the wing with a second-hand wing. My knowledge of the second-hand salvage market makes me doubt I could get an exact match that didn't need any work doing to it.

Internet prices for second-hand wing panels are £40 and upwards which is a lot to gamble on. And while that is still a possibility, commitment to the task has always been lacking....

Reckon I would rather spend that £40 on materials and learn some new skills.

Having removed all the remaining lacquer, I initially tackled the dent by using some small 'suction-cups' to help 'pull' the dent out. This worked to a limited degree, leaving a dent with a max depth of 4mm.

The dent lies on the shoulder of the wing. It's not that easy to see when the surface is matted down as the two photos above show. The dull matt surface is the weathered colour coat minus its lacquer coat. Also shown is the faded wheel arch eye-brow.

MATERIALS USED.

A small tube of 'Isopon P38' body filler was purchased together with a can of grey primer and a tube of knifing putty ( Holts Cataloy). I already have a selection of wet and dry grits, lacquer and rubbing compound left over from last year's efforts. All I really need to purchase now is a can of colour matched paint, but not till that dent is removed.

METHOD.

Luckily, the original paint layer has not been breached so there is no corrosion to deal with.

I started to gently rub down the dented area using wire wool and 180 grit paper. Clean the area of dust and grease and then apply body-filler straight to the treated area. A good tip I picked up online is to use a straight-edge to help shape or 'form' the filler to the surrounding panel.

I noted that the profile of the wing shoulder is 'flat' going straight up and down over the dent area. Lengthwise (ie.- going left to right over the dent), the shoulder profile has a slight convex radius so using a straight-edge 'former' is only possible while going straight up and down.

I ended up using the small handy plastic spreader used to mix the P38 paste to both apply and also 'form' the repair. A cloth was used to wipe off the excess paste from the former as I went along.

The first few passes were, it turns out, the best. I decided to try and fill a small imperfection by adding more filler and forming it again. The passing time only allowed the paste to start its curing process and as a result it would not 'form' as smoothly as it did before.

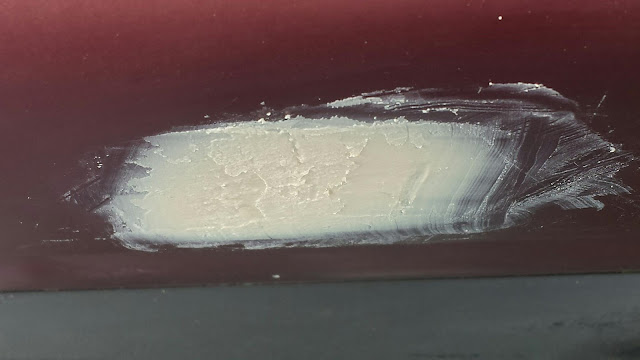

Two views of the first fill showing it's ruffled surface formed as the paste began to cure. Initially the filled surface was a lot smoother but I just wouldn't leave it alone!!

The lesson here is to work smooth, quick and to be confident and leave the area alone to set. You can always rub down and repeat as necessary. Although it's only a small dent, there is no need to get it done and filled in one go. I will have to sand back more then if I had left it as smooth as on the first pass.

I began sanding the filler using a spare 180 grit paper wrapped around a rubber eraser and used the black plastic spreader as a straight edge gauge.

It's important to use the sandpaper 'dry' at this stage as the filler can still absorb moisture and therefore cleaning the paper regularly is necessary.

I used gentle pressure and straight up and down strokes to follow the wing profile. It only took a minute to get up this stage. P38 filler sands real easy so it's possible to take off more then is necessary.

Regular cleaning and checking of the profile using the straight edge is recommended. Enlarging the above photo will show the inevitable surface imperfections that need re-filling.

After a quick wipe down with a brush and a dry cloth to remove the dust, some 'Holts Cataloy' paste was used to fill the imperfections.

The Cataloy paste comes ready mixed and a small smudge really does go a long way. It's ideal for filling surface imperfections and scratches, and sure saves on mixing up more P38 to fill the nicks left on the surface.

It dries quickly and sands easily. It may be necessary to repeat its application, remember, patience is a virtue.

TODAY'S VALUABLE LESSON.

Having progressed the repair as above to a nice smooth finish, I checked the area again with a larger straight edge, (a plastic 12 inch ruler) only to find the repair area now had a gentle 'dip' in its surface! This 'dip' could also be felt by rubbing my hand along the wing shoulder. Back to square one!

The photo above attempts to show the gentle 'dip' over the repair area. More filler needed!

The lesson learned is don't just concentrate on the immediate repair area, but keep an eye on how it blends with the bigger surrounding area.

I can't decide if the 'dip' is from too much sanding back, or not enough filler applied in the first place?

Running a hand palm along a body panel is a really good way to 'feel' gentle dips or bumps along the surface.

At this stage, I was about to spray some grey primer on the repair. I was a little curious to see if the gentle dip in the surface would be visually detectable?

I decided, correctly, to apply more filler.

It took just a little smudge to bring the surface level back and it was formed with the bigger straight edge in just two 'passes'. After drying and a quick rub down more Cataloy was applied to the inevitable imperfections.

Once the Cataloy had dried and was itself rubbed back, I decided it was time to spray some grey primer onto the repair area.

Having masked off above and below the repair area, the spray of grey primer now acts as a sealer and a guide coat for further work.

If the above photo is enlarged, some small surface imperfections can still be seen on the grey primer and they will be filled with more Cataloy paste before another coat of primer is applied. The top colour coat will be applied over the entire wing panel.

Also visible in the above photo is the rough, weather worn surface of the wheel arch brow which was sanded back in preparation of painting it black once the wing has been re-sprayed.